Development of technical, cross-domain solutions

Working as a self-employed engineer I combine the areas of hydraulics, electronics and software that would otherwise be singled out in different roles. This decreases development time, simplifies integration and helps to create feasible solutions right away.

Technical concept development

Creating a feasible solution

There are many ways to turn an idea into a product or prototype. Not all of them are however realistic in terms of price, time-frame or other factors. With the help of some experience the usual culprits can be avoided.

Industrial prototyping

Bringing concepts to life

Turning concepts into real-life hardware can be tough. Sometimes it’s better to start with some intermediate steps. Oudeman.io can help with building pragmatic prototypes that allow you to evaluate the idea.

System integration

Making it all work together

Development of technical systems usually involves many specialisms. Oudeman.io doesn’t deliver just one but has in-depth knowledge of all techniques involved. This can help for overview of a large project or to quickly develop a prototype in-house.

WHAT is oudeman.io GOOD AT

Skills and Experience

PLC programming

Programming HMI and PLC systems by Siemens, Beckhoff and Codesys. Using Tia-Portal, Simatic manager and WinCC (Flexible), Codesys development environment and TwinCAT system.

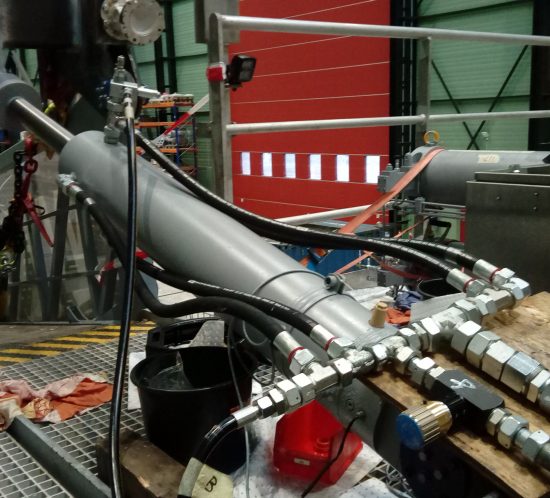

Hydraulic systems

Design, assembly and commissioning of hydraulic systems for position control, energy storage and propulsion. Experience in previous projects has given me a network of skilled suppliers to manufacture custom components like manifolds, PTA's and cilinders.

Electrical systems

Design, manufacture and commissioning of Electric systems. For various project I have created the blueprints for drive trains and cabinets. Together with experienced suppliers I can create the right equipment for any electrical setup.

Electric Drives

Programming and Commisioning of motor drives by Siemens, Vectron/Bonfiglioli, Lenze and Control Techniques.

Safety

Analysis and implementation of safe design. FMEA based safety strategies for the programming of Safety PLC's, design of Cabinets and compliance with guidelines. Using Hardware only or Siemens Distributed Safety and Beckhoff for local and remote safety solutions.

Virtualization & Simulation

PC and PLC virtualization projects for simulation of networks, communication and hardware. Possible hardware in the loop tests for PLC's and virtual commissioning.

Construction

Actual experience in on-site contruction of large machinery, hydraulics and electrics. Working alone, as foreman or next to sub-contractors, depending on the size of the project.

LoRa & RFID

(Low Power) Long Range radio solutions for monitoring of remote sensors. A backend for the user can be delivered depending on the desired functionality. RFID identification solutions for production or management of storage. I have used RFID in combination with PLC's to track production at Protix.

Embedded Linux and Microcontrollers

RPi Linux solutions for web connected devices like client counters and embedded microcontrollers for LoRa and small control systems.

WHat did oudeman.io do

Previous projects

Browse various projects done by oudeman.io over the past years. The projects should give some insight in the possibilities.

WHO is oudeman.io

Lead engineer for hire

Oudeman.io started out in 2014 (by then known as Echt-Zeit). Trained as an Industrial Engineer and further experienced as Automation Engineer at Ampelmann and Ampyx, I was looking for a job that would always be challenging and new. A job that would get the most out of my biggest asset: being able to use my broad technical interest and knowledge to create cross-domain solutions.

Rene at work in marine testing facility Trondheim for motion compensation system on new vessel type.

CONTACT

any question? please contact

Address

Harstenhoekweg 60

2587SM Den Haag

Phone

+31 (0) 624870118

Please use the form or Phone